“Close the door when you come in from outside, the A/C is on and you’re letting all the cold air out!” We all heard it in the summer as kids, but little did your parents know, that exact piece of advice applies to your business’ Walk-In Coolers, Freezers, and other refrigeration units like Refrigerated Reach-In Storage Freezers.

Hot summer days may increase traffic to your Walk-In Cooler for bottled water or beer, but with that extra traffic comes additional heat and humidity. In our blog post “Cut Your Walk-In Expenses During Slow Times,” we calculated that a smaller Walk-In Cooler or Freezer can cost roughly $5.00 per day to operate, while a larger Walk-In can cost as much as $10.00 per day or more. These costs are likely to rise as humidity, heat, and traffic in and out of the Walk-In rise, but there are ways to limit the impact!

Use Proper Loading Technique

The hotter the temperature around the Walk-In (ambient temperature), the hotter the air that enters the Walk-In every time the door is opened. If possible, try to avoid loading the Walk-In during the hottest part of the day. Instead, aim for mornings or evenings when it’s cooler.

Regardless of what time the Walk-In is loaded, there are a few tips you should follow. To echo your parents’ advice, “close the door behind you.” While loading the Walk-In, minimize the number of trips in and out, and do not prop open the door. Every time the door is opened, hot air enters, requiring the refrigeration to cycle more often or longer—and each of these cycles equates to additional costs.

Also, while stocking the Walk-In, be sure to maintain proper spacing around the evaporator coils (in simple terms, the fans) and the Walk-In wall panels to allow for proper air flow. No product inside the Walk-In should be stacked higher than the lowest part of the evaporator coils nor stacked in front of them. Likewise, all product should be stored at least 1” away from the wall panels. This will prevent excessive frost and ice buildup and will help make sure the coil is properly cleared during defrost which will keep the Walk-In running smoothly and efficiently.

Maintain Cleanliness

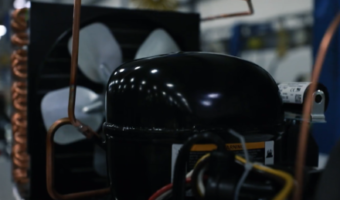

If you’re only going to listen to one tip from this blog, it should be this: keep your equipment clean! A dirty condenser coil will result in a less efficient refrigeration system and force longer cycle times to reach the desired temperature. If the condenser coils are dirty enough, it’s possible it may not even be able to cool down to the desired temperature, which is why keeping your condenser coils clean is so important.

Why exactly does a clean condenser lead to a more efficient cooler? Technically, the refrigeration system is not pumping cold air into the Walk-In, but rather removing heat via the refrigeration. The condenser coils’ job is essentially to release the heat outside. If they’re dirty, less heat can escape outside and therefore more heat stays in your system. When heat is in the system, the refrigeration cycles longer and in the end, costs you more money.

Keep Up with Maintenance

Similarly, preventive maintenance is also key to reducing operational cost and increasing reliability. We maintain our vehicles with oil changes, tire rotations, and inspections to increase reliability and hopefully prevent costly repairs in the future. Refrigeration equipment is no different. Proper preventive maintenance will ensure the most energy efficient operation.

- Regularly clean and inspect condenser and evaporator coils.

- Inspect copper lines to make sure nothing is rubbing or vibrating in a way that might cause a leak.

- Inspect wiring for loose connections and frayed or burned wires.

- Inspect electrical components, such as contactors, for pitted or burned contacts.

- Ensure the door sweeps are in good shape.

- Inspect gaskets on all service / entry doors for proper seals.

- Inspect glass door gaskets and check for proper seals.

- Be sure strip curtains are in place and not damaged.

Any warm air and humidity that you keep out of the Walk-In will equate directly to cost savings. That’s why most of the maintenance tips revolve around ensuring your Walk-In has a tight seal.

Utilize Proper Settings

If you don’t need your Walk-In Freezer at -20 degrees F, turn the temperature to a warmer setting. Same goes for a Walk-In Cooler that is set colder then needed. There are some items, such as ice cream, that require special temperatures, but otherwise we often see Walk-In Coolers and Freezers set to temperatures lower than needed. Choosing a warmer temperature within the safe zone for your items helps prevent excess refrigeration cycles and cycle times, which (you got it!) saves money.

All control settings, including temperature and defrost times, should be optimized. Some of this can be done by store associates, but the majority of it should be performed by a refrigeration contractor.

Select Proper Accessories

It’s very common for Walk-Ins to have lights. Their impact on the overall running costs are minimal, but every little bit helps. We recommend using LED lights, which use less electricity than both fluorescent and incandescent light bulbs. Depending on the Walk-In layout, it’s possible lights do not need to be turned on all the time. Instead, lights can be connected to motion sensors to make sure lights are on when people are present and turned off when the Walk-In is not occupied to save on energy costs.

HVAC-R is a Team

Control the surrounding ambient temperature of the Walk-In. Maintaining temperature and humidity around the Walk-In will help minimize introduction of warm air and humidity every time the Walk-In is accessed.

Walk-In Coolers and Freezers are great for keeping product cold but are not designed to remove humidity. Air conditioning systems will do a much better job and will be more cost effective. Therefore, our final tip is to make sure your Air Conditioning system is up and running properly.

In the hottest days of summer, your Walk-In will most likely require additional cycles and longer cycle times to maintain the proper temperature. But by following these tips on how to keep Walk-In refrigeration costs down during the summer, you’ll put your business in the best possible position to save on energy costs all season long.

If you enjoyed this blog, subscribe to our temperature-controlled storage solutions newsletter!